Monthly Deals Custom Anodized Aluminum 6061/7075 CNC Machining Parts for Electric Scooter

Ningbo Yongnan Machinery Factory was set up in 2009 with an area of 9,000 square meters . The company specializes in mou

Send your inquiryDESCRIPTION

Basic Info.

| Pressure Chamber Structure | Vertical |

| Tolerance Grade | 6 |

| Casting Surface Quality Level | 3 |

| Certification | RoHS, ISO 9001:2000 |

| Brand Name | OEM |

| Service | One Stop-Shop Service |

| Tolerance | 0.005mm |

| Company | Factory |

| Experience | More Than 10 Years |

| Address | Ning Bo |

| Transport Package | Seaworthy Packaging |

| Specification | 0.2-1 |

| Trademark | yongnan |

| Origin | China |

| HS Code | 8408201010 |

| Production Capacity | 100000 |

Product Description

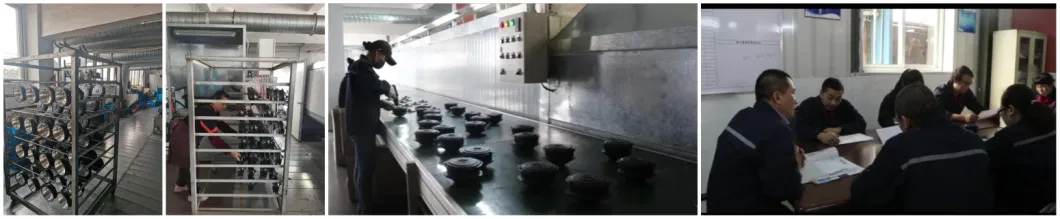

Ningbo Yongnan Machinery Factory was set up in 2009 with an area of 9,000 square meters . The company specializes in mould development, designing tool and fixture, machining of e-bike motor parts, e-scooter parts and precise gear hobbing. The company not only establishes a stable strategic relationship with domestic first-class motor companies, but also exports to Europe, United States, Japan and other countries. Ningbo Yongnan Machinery Factory provides one-stop shop that involves mould development, designing tool and fixture, aluminum die-casting, CNC and painting . The company has more than 100 equipment which cover 20 sets of precise four & five-axis machines; 2 sets of gear machines; 4 sets of robot arms; 60 sets of precise turning-milling and multi-station machines; 20 sets of multi-axis drilling machines; 3 sets of die-casting machines; advanced detector equipment and automatic painting line . The company has 87 employees which include 12 management staff, 5 senior engineers, 10 technical staff, and 10 QC staff. It has passed the quality management system standard: GB/T19001-2016 idt ISO9001:2015. In 2019, the company participated in the "Hundreds of Enterprise Promotion" project, actively promoted digital transformation of the industry and introduced the advanced Neural-MOS intelligent production operating system V6.0. Pursuing breakthroughs with reforms, promoting improvement with innovations; seeking development with quality, building brands with integrity; winning customers with service and promoting development with win-win are the values that our company has always adhered to. Our company is always committed to providing customers with higher quality products.| One-Stop Shop Service: | Mould design and manufactureDesigning tool and ficxureAluminium alloy die casting ADC12 A380Turning-milling, drilling and CNC machiningSurface treatmentFull inspectionPacking |

| Equipment | Die casting machine:200T/280T/400T/500T.CNC centers, CNC turning, CNC lathes,milling, multi-axis drilling, Automatic painting line |

| Surface Treatment | Polishing,Cleaning,Painting( Black or Silver ) |

| Application | E-bike Motor E-scooter Bike |

| Staff | 12 management staff 5 senior engineers10 technical staff10 QC staff 50 workers |

Our Advantages:

1.One stop-shop service to our customers.2. Customized with client's requirement3.Closing to Beilun port & Saving transportation distance3.Equipped with all kinds of Machines4.More than ten years experience

FAQQ1:Are you manufacturer?

A: Yes, we are. Our company was set up in 2009 with an area of 9,000 square metersQ2:What's your lead time?

A:Mold manufacturing time:It depends on the product size and structure, usually the mould making lead time is 25 to 35days,die casting production time;according to the steps and complexity of product processing,and the quantity of the order.Q3:How to control the quality?

A:We have QC department and do full inspection for production.Q4:What kind of businesses can your provide?

A: Our company specializes in mould development, designing tool and fixture, machining of e-bike motor parts, e-scooter parts,precise gear hobbing and automatic painting line. Q5:Why do we need3D file and 2D drawing?

A:The 3D file is very useful,but there are some other requirement not indicated like the tolerance and the surface treatment .This is why the 2D file is needed

FAQQ1:Are you manufacturer?

A: Yes, we are. Our company was set up in 2009 with an area of 9,000 square metersQ2:What's your lead time?

A:Mold manufacturing time:It depends on the product size and structure, usually the mould making lead time is 25 to 35days,die casting production time;according to the steps and complexity of product processing,and the quantity of the order.Q3:How to control the quality?

A:We have QC department and do full inspection for production.Q4:What kind of businesses can your provide?

A: Our company specializes in mould development, designing tool and fixture, machining of e-bike motor parts, e-scooter parts,precise gear hobbing and automatic painting line. Q5:Why do we need3D file and 2D drawing?

A:The 3D file is very useful,but there are some other requirement not indicated like the tolerance and the surface treatment .This is why the 2D file is needed

Related Products